LNG Storage and Refilling Station

-

LNG ISO Storage Tank Container 45FT

LNG ISO tank container, 45ft:

Email Details

Water capacity: 52.3 m3.

Dimension: 13716mm*2438mm*2591mm(L*W*H).

Standard: ISO, ADR, BV inspection; -

Cryogenic LNG Storage Tank 500L

Application from city bus, truck to loader, marine boat, etc.

Email Details

OEM quality by heavy duty truck manufacturer, more than 15 years experience.

To follow our working procedure to start conversion. -

Hot

Skid Mounted LNG Refilling Station

LNG quickly-mounted refilling station where functions are highly integrated on the skid which can achieve quick on-site installation and LNG fueling services directly.

Email Details

1. High assembly, integrated design, small required area;

2. Pre-assemble, inspect strictly, small installation work on site, can put into use quickly;

3. Container similar design, it is easy to transport, good mobility;

4. Advanced procedure, has a good speed unloading and filling;

5. The key parts are imported, the electrical system is explosion-proof design, safety and reliable;

6. PLC auto control, human machine interface is very well, easy to operate. -

ASME Approved LNG Storage Tank ASME

LNG storage tank:

Email Details

1. Adopt double-wall vacuum powder thermal insulation technology.

2. Apply high-quality ultra-low temperature thermal engineering expansive perlite as filling. Take helium-spectrum leakage test for complete cryogenic liquid tank. Good thermal-insulating effect, low evaporation loss and long life time.

3. Imported paint makes appearance more beautiful and longer anti-corrosion time.

4. Compact tank structure, advanced piping and flow-process design make operation simpler and safer as well as maintenance and repair easily.

5. Vertical type and horizontal type.

We are able to design and manufacture cryogenic liquid storage tanks in various different volumes and pressure grades as per GB150 and ASME standard. -

Cryogenic LNG Storage Tank 1000L

High quality approved by OEM heavy duty truck manufactuer in China.

Email Details

Offers three years quality warranty, BV inspection report.

Different sizes available from 150L to 995Litres capacity. -

Cryogenic LNG Mobile Refilling Trailer

LNG mobile refilling trailer:

Email Details

1. Low requirement for site conditions, easy installation, thus the speed of building a station is very fast, is one of the best ways to build a temporary filling station;

2. Less investment, small floor coverage, low operating costs;

3. Short pre-cooling time, fast filling speed, less emission, high integration: analyzing through the compare of the skid station and mobile filling trailer, the skid station needs 5 minutes to precool, the mobile filling trailer needs only 1 minute; the skid station filling double cylinders need 7 minutes, the mobile filling trailer only needs 5 minutes; the pipe of mobile filling trailer is short, reduce emission;

4. Low transport costs: mobile filling trailer has the tanker features, is truly the combination of mobile stations and transportation storage, which can reduce the cost of transportation;

5. Flexible: can be used as a temporary station, and realize the function of mobile charging and emergency rescue. Equipped with power supply, both external power supply and self-generating can be used;

6. Safe and reliable: with natural gas leakage automatic alarm, emergency stop system. -

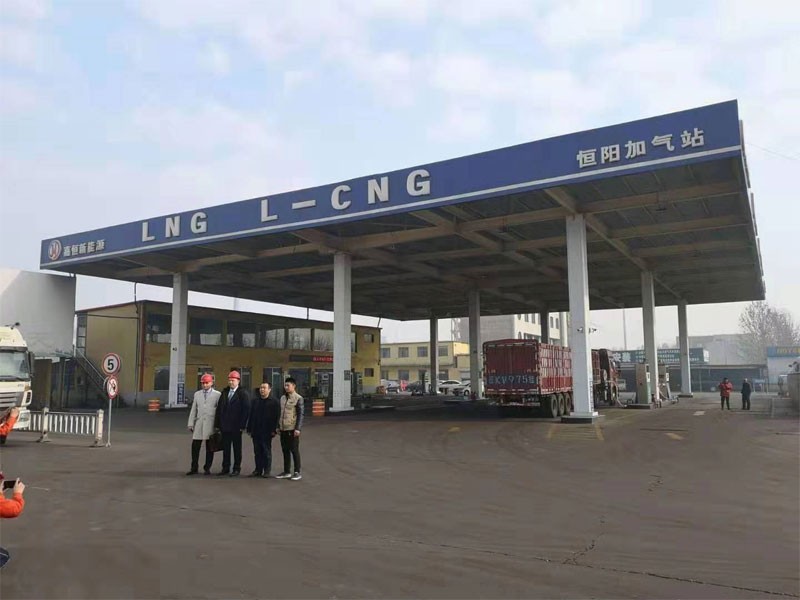

L-CNG Station

L-CNG Station:

Email Details

1. Monitoring and management for LNG storage tank, cryogenic high-pressure piston pump, process valves and dispensers;

2. Automatic switch and control for operating code among unloading, pressure of regulating, gas refilling, standby, etc.;

3. Data collection, inquiry, storage and reports form printing;

4. Alarm and faults diagnosing. -

Integrated LNG Refilling Trailer

It is a LNG refilling station on LNG trailer, with LNG pump, dispenser,

Email Details

self-booster, LNG refilling hose; It could do refilling to LNG truck,

LNG fuel ship at port, or for emergency backup refilling. -

Integrated LNG Refilling Skid With Tank And Dispenser

Integrated LNG Refilling Skid where functions are highly integrated on the skid which can achieve quick on-site installation and LNG fueling services directly.

1. High assembly, integrated design, small required area;

2. Pre-assemble, inspect strictly, small installation work on site, can put into use quickly;

3. Container similar design, it is easy to transport, good mobility;

4. Advanced procedure, has a good speed unloading and filling;

5. The key parts are imported, the electrical system is explosion-proof design, safety and reliable;

6. PLC auto control, human machine interface is very well, easy to operate.integrated LNG refilling skid integrated LNG refilling skid with tank integrated LNG refilling skid with dispenserEmail Details